With over two decades of supplying some of the biggest brands in the business, MAGMA Brakes is a global leader in replacement brake part manufacturing and distribution. We are the manufacturer behind the manufacturer.

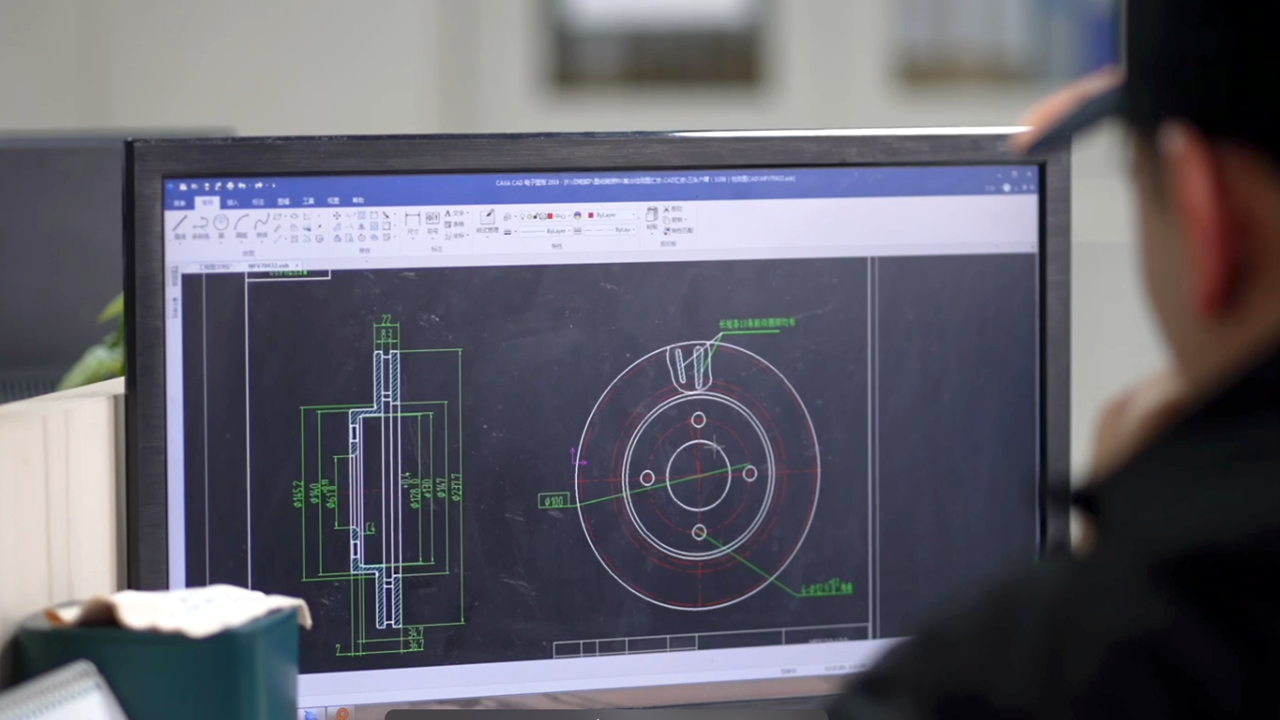

MAGMA reverse engineers each replacement disc and pad to match OE form, fit & function. We capture critical dimensional data and formulation performance data to ensure each part will fit perfectly every time and deliver reliable, like-new stopping power.

- First to market with new applications.

- CMM and FARO reverse engineering systems.

- Global OEM part sample reference library.

- IATF 16949:2016 - Quality management certified.

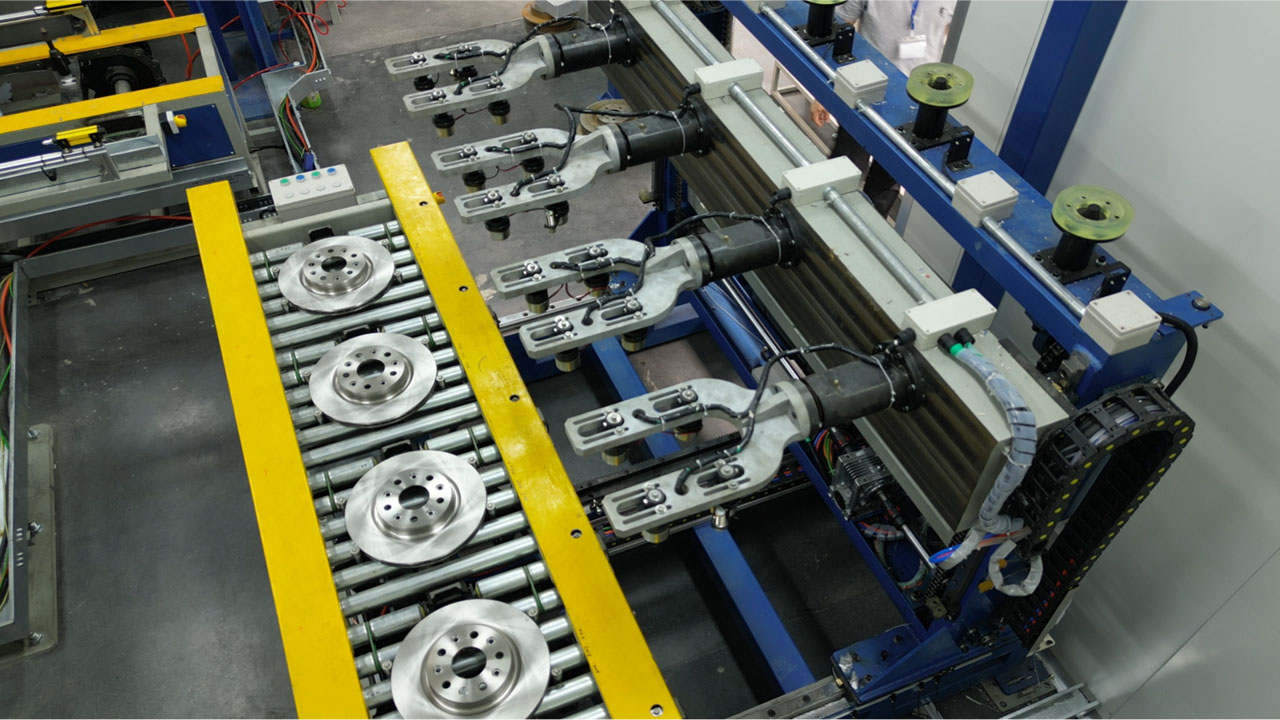

Fully automated brake disc and pad factories utilize advanced robotics and artificial intelligence (AI) to improve efficiency and product quality. These state-of-the-art facilities produce parts that match OE form, fit, and function.

- Partnership with FANUC Corporation.

- In-house programming and development team.

- Autonomous, collaborative production cells.

- Continuous process and product improvements.

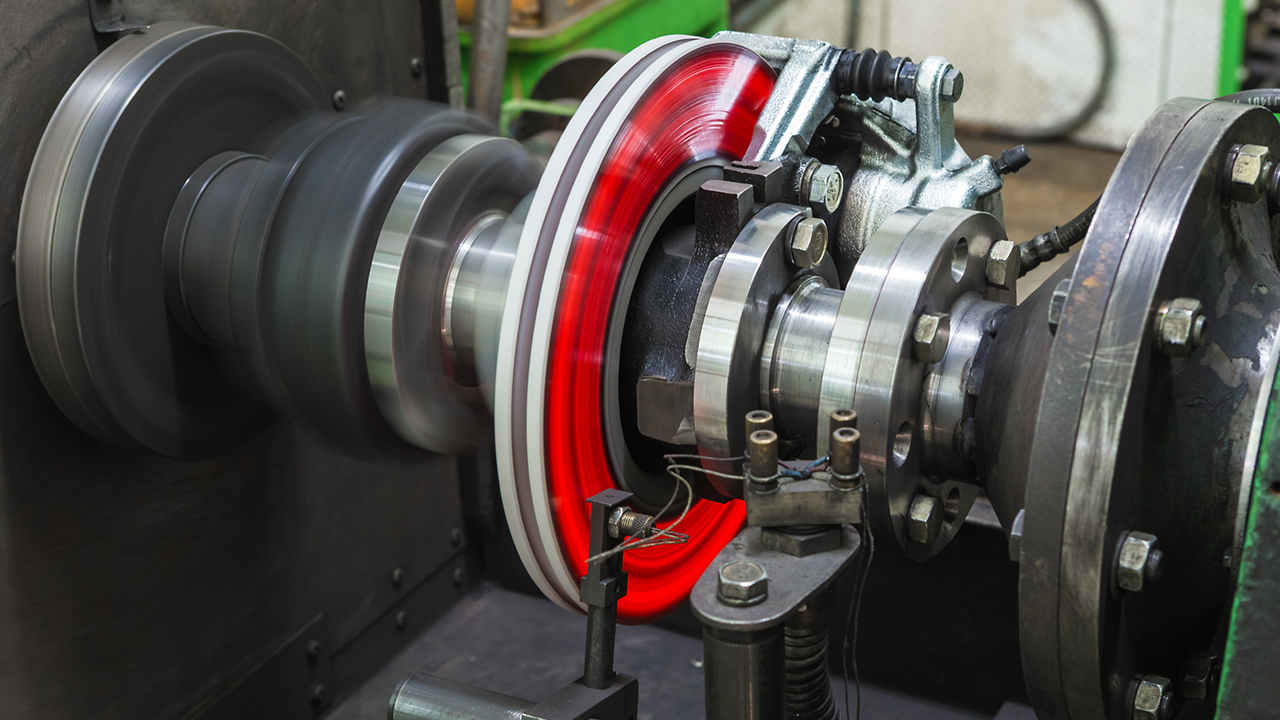

The MAGMA engineering team tests each friction formula and brake disc to analyze real-time noise, vibration, and harshness (NVH) data. This information supports the continuous improvement process, driving product evolution.

- Multiple in-house LINK dynamometers.

- Dedicated on-site metallurgy testing lab.

- Next-generation friction development.

- ECE R90 - European brake performance specification.